In modern manufacturing, speed and accuracy depend on automation. The pneumatic cylinder is the heart of numerous automated systems. It converts compressed air to controlled mechanical motion. Even the most advanced machines are susceptible to malfunctions, failures of systems, and delays in production without well-engineered cylinders. This is why choosing the right pneumatic cylinder manufacturer is one of the most important commercial decisions an industrial company could make.

There are many different suppliers of pneumatic cylinders offer the same level of reliability. Some vendors only offer off-the-shelf items but others develop solutions to meet real-world operational needs. The condition of the cylinder affects everything from energy efficiency to maintenance costs and long-term durability. If the cylinder is not constructed correctly, it can leak, exhibit irregular motion, and experience early breakdown of the components. This can lead to lengthy downtime and lost revenue.

What Custom Pneumatic Design Improves System Efficiency

The main difference between standard pneumatic cylinder providers and professional manufacturers lies in the ability to customize. The industrial environments are very diverse. Machines are subject to a diverse range of loads, temperatures and pressures. A factory line for assembling electronics doesn’t require the same structure like a steel plant that shapes components.

The manufacturer of a pneumatic cylinder should allow engineers to customize bore sizes, stroke lengths, rod diameters and pressure ratings based on their exact specifications. Custom engineering increases efficiency by adjusting the actuator’s behaviour precisely to mechanical load and movement frequency. This prevents excessive wear on the components, thus extending their lifespan.

Modification of the material is a different element. Cylinders used in outdoor, chemical, or high-humidity environments require special alloys and coating treatments to stop wear and corrosion. The option of customizing is not available for the most advanced manufacturers and is crucial in ensuring the safety of performance.

A manufacturer that Engineers Solutions and Not Just Products

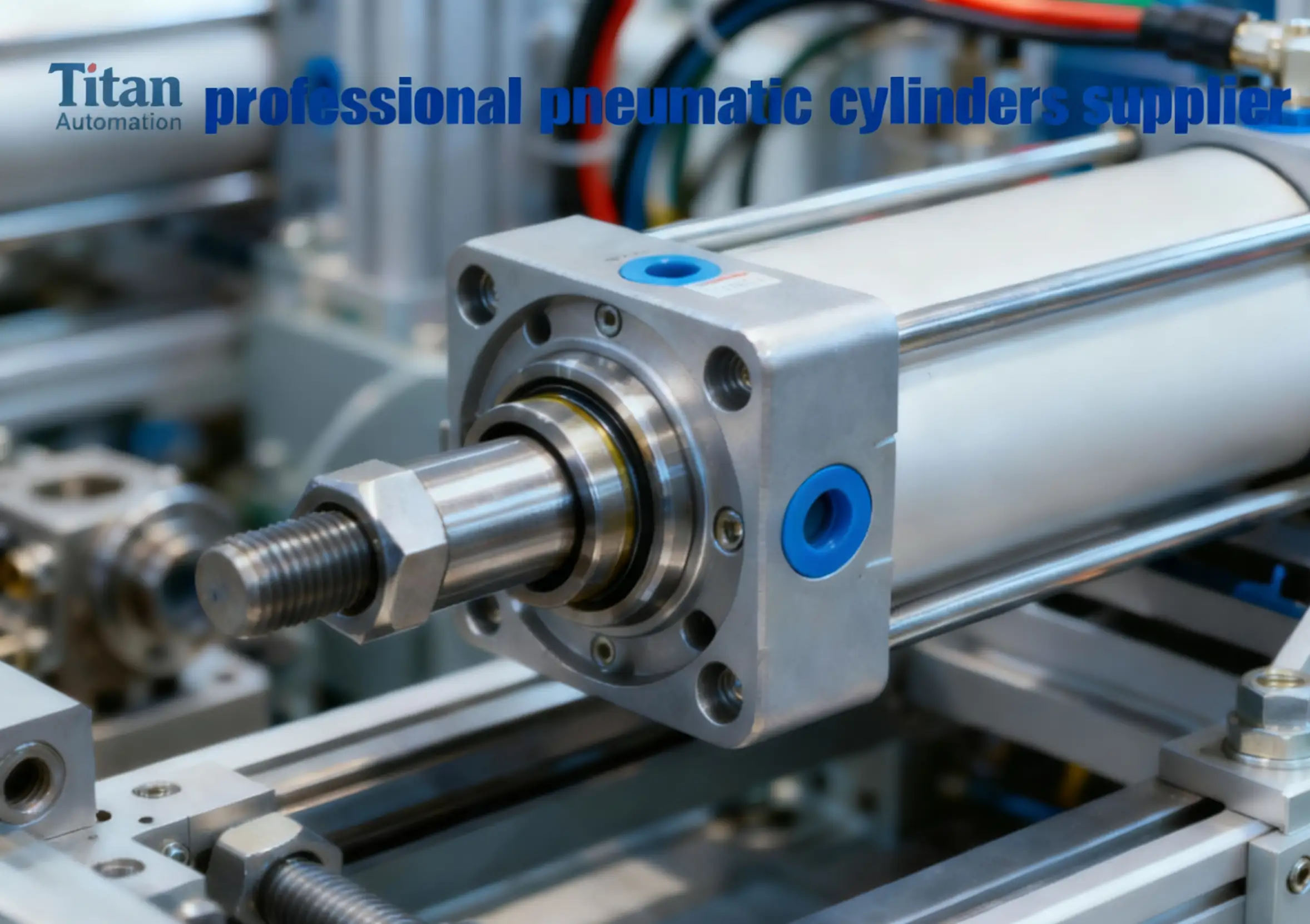

Titan Automation is an air pneumatic cylinder maker that specializes in research development, manufacturing services, as well as sales of pneumatic air-cylinders. They also offer a variety of custom pneumatic items.

This statement is more than just branding, it represents the reality of production. They ensure that every cylinder is up to standard by managing 90% of the manufacturing process, from machining through assembly. Vertical manufacturing eliminates quality gaps created by third party suppliers and ensures that every part is specifically designed to perform.

Titan Automation has experience that is more than pneumatics. With a long mechanical engineering background and over 26 years of experience in production of pneumatics, they bring technical wisdom that only time can develop. They can swiftly adapt to the demands of international markets, custom design requests as well as their OEM capabilities without outsourcing vital actions.

Why Manufacturing in House Makes A Difference

The quality of the product increases dramatically when a manufacturer handles most of the production procedures within its own facility. Every stage the selection of materials, machining, sealing, finishing and testing is carefully monitored. This improves mechanical consistency and reduces tolerancing errors.

Outsourcing is an essential part of many pneumatic cylinder manufacturers’ business. This means that their materials are inconsistent, production quality is variable, and dimensions aren’t controlled. The responsibility for problems becomes unclear. However, a fully integrated manufacturer can track problems right at the source. Solutions are faster, and quality becomes predictable.

The Total Pneumatic System: More Than Cylinders

A professional manufacturer never focuses on the isolation of its products. Pneumatic systems work as networks. Cylinders should be able to seamlessly integrate with fittings, valves, air regulators and control systems. When all components are working together and airflow is steady, pressure within the system is regulated and performance is predictable.

The top manufacturers of pneumatic cylinders recognize this and offer complete automation systems instead of standalone components. Integrated solutions lead to fewer compatibility issues and smoother operation across the entire production line.

Final Thoughts on Choosing the Best Manufacturer

A pneumatic tube is more than a simple steel pipe. It is precise in motion. It is system reliability. And ultimately, it is the success of production.

Choosing the right pneumatic cylinder manufacturer protects equipment investment, prevents unnecessary downtime, and drives consistent output. The top pneumatic cylinder manufacturers are not only able to supply components, they offer reliability in engineering. It is not by chance that automation goes on for a long time. It’s a good design.